Bridging the Gap between Design and Manufacturing

You have a clear product concept, but you need help finalizing a design that’s cost-effective and efficient to manufacture at volume.

Sweeney Metal Fabricators helps project managers and mechanical engineers bring important ideas to life by partnering with their teams to optimize designs, build prototypes, and manufacture high-quality parts and products with repeatability.

Optimizing Your Design for Manufacturability

Whether your design exists as a basic drawing or a fully fleshed-out model complete with GD&T callouts, we’re equipped to review whatever it is you have and make recommendations for optimizing manufacturability.

As your design collaborator and manufacturing partner, Sweeney Metal Fabricators focuses on helping you problem-solve to achieve the best possible results. With 30 years of experience as the Northeast’s premier fabrication shop, we’re known for providing exceptional service and solutions. Here’s what you can expect from our team:

Design optimization—not ownership

Regardless of how much we assist with your design, you retain ownership of your concept and creation from start to finish. The idea is yours. We’re merely the implementers.

Confidential communication

Our interactive, online quoting system is ITAR-compliant, so you can share your files and product information with our machine shop and be confident your content is 100% secure. If your project requires an NDA, simply send it to us, and we will review and sign it the same day.

Time-tested and transferable designs

We co-develop designs that stand the test of time. While we hope to remain your preferred manufacturing partner for years to come, we recognize the importance of flexibility for our customers. That’s why we specialize in designs that are:

Easy to manufacture and assemble

Made with common components

Transferable to other top-tier manufacturers should that need arise

You Need a Manufacturer, Not a Magician

Of course, we’d love to wave a wand and *POOF* bring your idea to life! But until we work out the kinks in our wand design, we’ll have to make do with implementing the best practices we’ve gleaned over our decades in manufacturing.

Most of the time, that means we’re tasked with identifying design elements that simply aren’t manufacturable or can’t be made within your target price range.

Cost-efficiency can be difficult to achieve, and some shops simply won’t look twice at a project with an initial scope that is bigger than the customer’s budget. At Sweeney Metal Fabricators, however, we love the challenge of helping our customers develop an excellent product at a sustainable price point.

If it can be done, we will do it. And if it can’t be done, we’ll tell you up front.

Sweeney Metal Fabricators vs. the other guys

Not every machine shop provides the same kind of solution-oriented services we offer. Some shops are simply set in their ways. They have a steady stream of “bread-and-butter” work coming in the door, and they see no need to expand beyond those projects.

Other shops don’t employ a team with the skills necessary to offer design guidance or tackle challenging machining jobs. These shops excel at manufacturing exactly what your design outlines—no more, no less, no changes.

Our team embodies an expert skill set and a desire to make the best products possible. Every operator on our machine shop floor is empowered to pump the brakes on parts that aren’t going to meet a customer’s vision.

This common-sense approach leverages our team members’ expertise to ensure an excellent experience for every customer, from the very first quote request to the day we deliver the final order.

How Sweeney Cut One Customer’s Costs by 70%

Our customer: an IT industry OEM

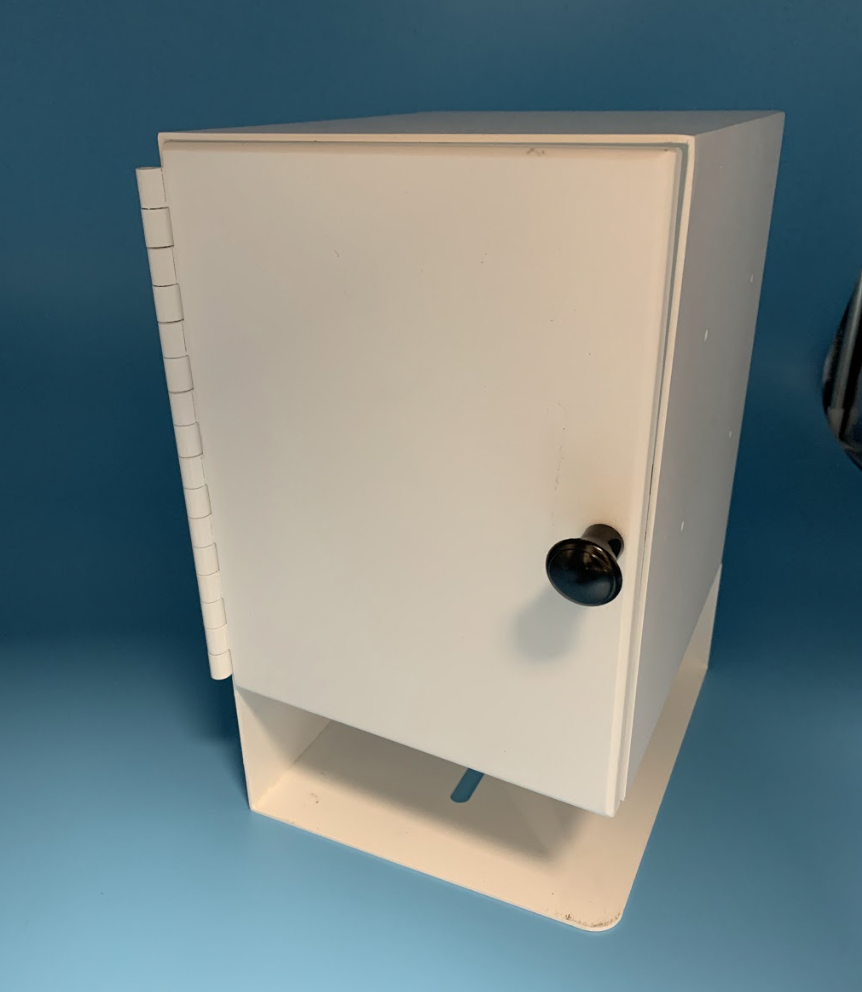

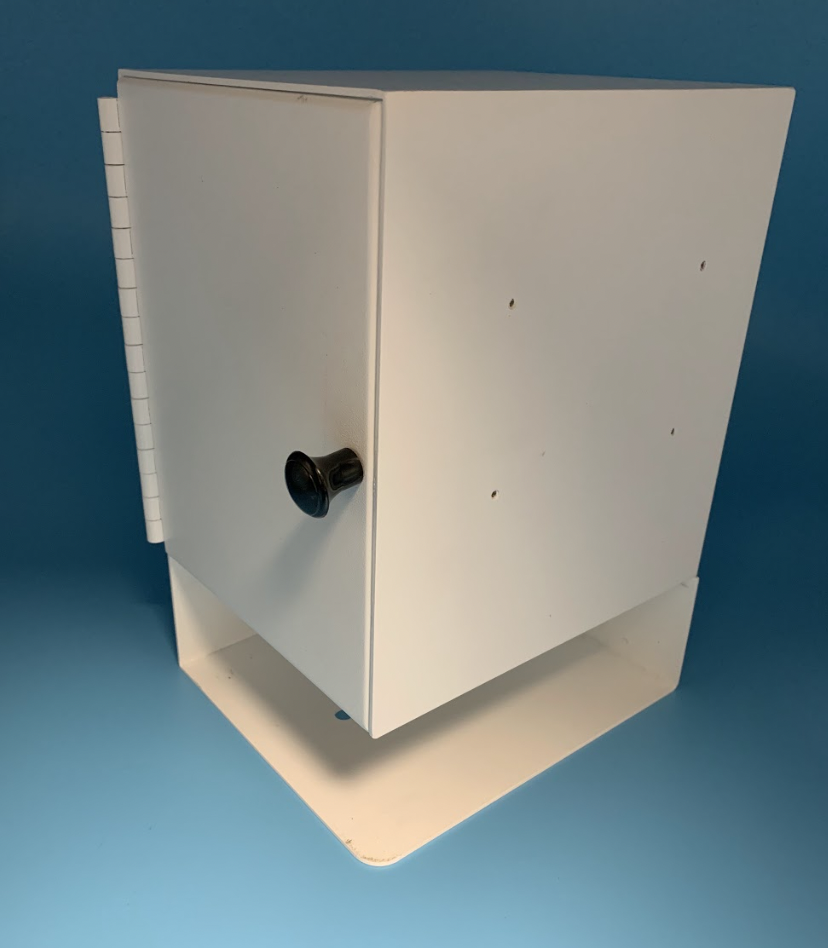

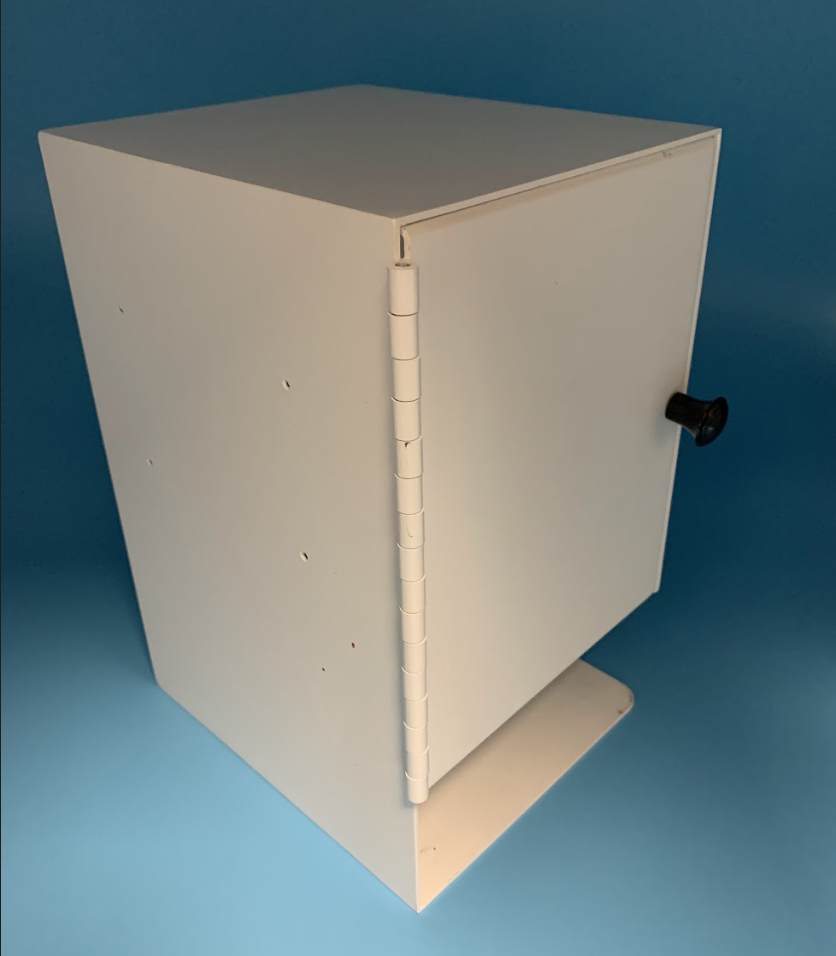

Their product: a heavy-duty lightbox destined for a healthcare environment

Developing a manufacturable design

This customer came to us with a rudimentary concept for a lightbox that would be installed in thousands of healthcare centers throughout the US. The product needed to be:

Heavy-duty enough for extensive use

Immediately repeatable at high production volumes

Manufacturable for $200 per unit

Perfecting the prototype

After developing the initial prototype, we began work with our customer to identify areas for improvement.

First, the design needed to be simplified to ensure rapid, high-volume manufacturability and assembly. Next, we had to cut the per-unit price from $700 to $200, a cost reduction of more than 70%.

Achieving optimized production and pricing

We worked quickly in collaboration with our customer’s team to modify the design, test revisions, and finalize an end product that could be easily manufactured and assembled by our machine shop or any other shop our customer might work with in the future. The cherry on top? We were able to bring the lightboxes to production at $200 per unit.

Thanks to a great partnership between both teams, Sweeney Metal Fabricators successfully designed a premium product that thrilled our customer and, more importantly, their end customers.

Creativity in Manufacturing

We’re fortunate to work with a wide range of customers—making parts for a high-risk aerospace application one day and implementing design solutions for a healthcare product the next. The diversity in our work challenges and motivates us, enabling our talented team to shine through creative manufacturing and unwavering customer care.

To partner with us on your next part or product, request a quote!